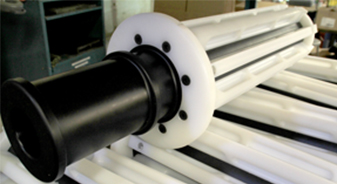

CSR has developed a number of different styles of core chucks to fit a variety of parent roll holding situations for customers across the industry. From 3” parent rolls on hard wound lines to 18” parent rolls on tissue lines we have a solution that will work for you. We consult with our customers on every order to insure they get a solution that will work for their application in their facility and will adapt the design of our chucks to work on your paper line with no engineering costs or fees. We have developed a number of different styles of core chucks to fit a variety of parent roll holding situations for customers across the industry.

“CONVERTING STOREROOM HAS BEEN A KEY SUPPLIER TO OUR CONVERTING OPERATION HERE IN CAMAS WASHINGTON SINCE 2005. During that time we have utilized their light- weight-ribbed core chuck solutions, their problem solving and design skills for custom projects, and have sourced a variety of replacement spare parts, for our converting equipment with them. We value the strong supplier relationship with Converting Storeroom and their consistent support of our operational needs.”